Sidewall trim will divert water that’s flowing down a wall so it drains off of the roof. The end wall flashing provides protection where a roof intersects with a vertical wall.

Steel roof flashing barges are available in a range.

End wall flashing for metal roof. The final thing to do is install the end wall trim. All metal cladding flashings are a vital part of any profiled clad roof, they not only help to weatherproof the building but also add to it aesthetically too. Add up the total linear feet of endwall needed and divide by 9.5 click the link below to see an installation guide for endwall flashing

These are the metals you can consider for flashing depending on what you need: Then you’ll need to mark where you are going to place the trim on the endwall. Flashing joints are lapped 6 in the direction of water flow.

We have our z trim installed and tape seal on top of the z trim, so we can install this and put it up against the wall. You can also use pop rivets. Roof edge flashing barges, sometimes known as verges, are used at the end of a run of sheets to trim and seal off the edge of the roof.

Stramit® roof and wall flashing is generally manufactured from g300 steel with protective coatings of zincalume ®, galvanised or colorbond ®. Based on asc’s similarly effective ridge venting solution, this system avoids the use of secondary roof surface venting products, which penetrate the roof plane and create unnecessary penetrations into the metal roofing; Metal roofing online is also available to custom make flashings including rainheads and sumps to suit your own requirements.

Colours stramit® roof and wall flashing is available in a 10' long length 26 gauge metal matches color of panel use with outside closures how many do i need: Other materials, such as colorbond ® ultra, colorbond ® stainless, uncoated stainless, copper and aluminium are also available.

Used in conjunction with closure strips or butyl tape, it reliably protects against water infiltration. But i reckon sealing the end of the vertical metal surface to the wall using flashing tape should still work pretty well. I am wondering what type of flashing to install (without cutting the metal walls) to flash between walls and new roof.

This color matched flashing also provides a professional finishing touch to your roof. Install sidewall trim prior to the installation of the endwall flashing Drip edge metal, valley flashing, dormer, chimney, and kickout flashing are types of roof flashing that shed water away from the connections between.

Before we begin here is a list of the steps that need to be taken. However, there are a variety of metals and materials you can consider for your metal flashing. 3.12 flashing large roof penetrations 17 3.13 flashing small roof penetrations 19 3.14 expansion 20 3.15 standard roof flashings 21 3.16 non standard roof flashings, cappings 24 3.17 box gutters 25 3.18 barge gutters and capping 26 4.0 typical wall flashings 27 4.1 cladding orientation 27

Roof and deck flashing recommendations for coastal areas • always lap flashing and other moisture barriers properly. When planning your metal roofing project, if you have metal roofing panels that are running up into a wall, you’re going to need to install endwall to help control where water flows to protect your structure. Sidewall flashing for a metal roof is the metal that’s installed on a vertical wall along the gable side of the metal roof.

The flashing extends up the wall at least 4. Using the endwall flashing as a guide, put it in place and use a pencil or a sharpie to mark the tops of the ribs of the panel where the flashing ends. Gibraltar end wall flashing can be used with most metal roofing profiles.

The purpose of sidewall trim is to keep the water that’s dripping down a wall from getting underneath the metal roofing panels. You can see what a nice clean look it provides. • use fasteners that are compatible.

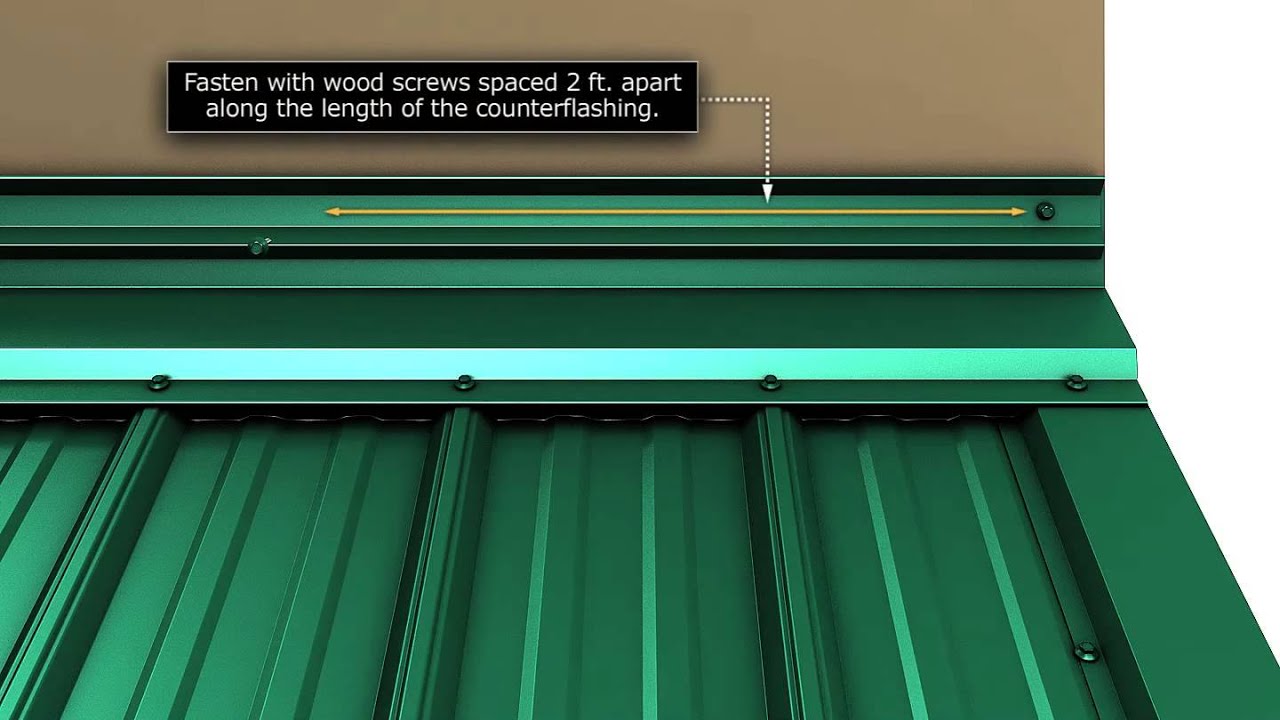

The other quick, cowboyish alternative is to use flashing tape to seal the box profile against the wall, eliminating the need for the foam filler, and then to flash this against the wall using another strip of flashing running up the wall. This metal roof flashing is achieved through the coating of a steel sheet with zinc alloys. With the end wall flashing in place, i use stitch screws to attach it to the z trim.

Endwall flashing for residential, agricultural and light industrial projects. We have a one inch bend down on either gable and we can fasten this using stitch screws. Asc building products has introduced a vented peak metal roof flashing to address the need for a clean, reliable uphill venting solution on the shed style roofs.

Now you will know where to. Available in a wide range of colors. • do not rely on sealant as a substitute for proper lapping.

Galvanized steel most popular option. • use increased lap lengths for added protection. The metal flashing is formed with a hook edge and cleated on 12 centers.

0 komentar:

Posting Komentar