Ball nose cutters or ball end mills (lower row in image) are similar to slot drills, but the end of the cutters are hemispherical. Plunge cutting leaves a scalloped edge (see diagram above) that will have to be cleaned up by a finish pass.

5 flute single end w/ flat 45° helix fine pitch center cutting tc carbide roughing end mill w/ ticn 3, 4 & 5 flute single end 20° helix center cutting tc carbide roughing end mill w/ altin 3, 4 & 5 flute single end 20° helix fine pitch center cutting tc carbide roughing end mill

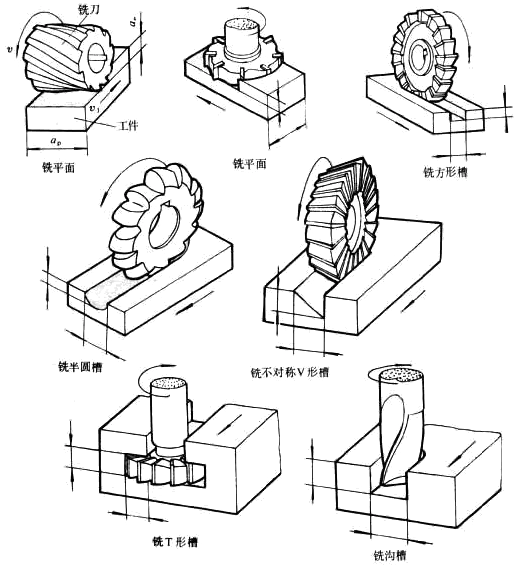

Roughing end mill cutter diagram. Slab mills are mostly used in a gang milling processes. Roughing end mills roughing cuts are generally for preparing the surface. By using roughing end mills, we obtain a rough surface finishing.

This type of cutter is used when you have to remove more amount of material from the work piece. Roughing end mills are also famous as “rippa” cutters. The cnc router community has some specialized types that are discussed in our cnc router cutter guide.

Side loading is dramatically reduced with lower helix angles, making it easier to mill thin walls. While traditional roughing is occasionally necessary or optimal, it is generally inferior to high efficiency milling (hem).hem is a roughing technique that uses a lower radial depth of cut (rdoc) and a higher axial depth of cut (adoc). This article is your total guide to selection and use of end mills, the most common type of cutter used by cnc milling machines and cnc routers.

This spreads wear evenly across the cutting edge, dissipates heat, and reduces the chance of tool failure. Computer numerical control systems offer less need for manpower and higher levels of automation. Some cutters with description 1.

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing. End mill coarse roughing pmx din844nr nz They are more beneficial commercially and are used in various.

It is a process where rotary cutters remove material, which makes it the. A roughing end mill the type with a wavy corncob outer flute cuts into the part at a higher ratio to the rotation. The spiral flute end mill compared to a straight flute does a similar function.

Definition, construction, diagram, working & uses. The milling cutter is the cutting tool. These lower the shock load during the cutter rotation both enabling a heavier cutting load.

The system response is recorded by an acceleration sensor (type pcb w356a03 nc) attached to the tool holder shaft opposite to the point of excitation. It is measured from the start of the necked portion to the bottom of the cutting end of the tool. The overall reach of an end mill, or length below shank (lbs), is a dimension that describes the necked length of reached tools.

Types of milling cutter tools and their uses [with pictures]. Click to browse corner rounding finishing/roughing end mills made by world class cutting tool manufacturer guhring. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds.

Coarse tooth roughing end mills remove large chips for heavy cuts, deep slotting and rapid stock removal on low to medium carbon steel and alloy steel prior to a finishing application. Cnc machining is a highly utilised subtractive manufacturing technology. The franken production facility is located in rückersdorf, germany, and is dedicated to the manufacturing of high precision end mills and indexable cutters as well as special design form and profile milling tools.

Their extreme hardness means they are brittle, so a highly rigid setup, such as a cnc machine, is necessary to prevent the end mill from. End mill fine pitch roughing pmx+tialcn din844nrf nz stainless. Rcwsf40 shell roughing end mill hss co5 ø 40 mm, in wooden box.

Shop our selection of roughing cutters for use with any end mill notcher that requires a 1.25 shank. One of these automated fabrication methods is cnc milling. Basically, slab mills are used for machining surfaces which are large as well as broad in shape.

Roughing end mills, also known as ripping cutters or hoggers, are designed to remove large amounts of metal quickly and more efficiently than standard end mills. Some end mills with fewer flutes are called roughing end. Roughing end mills are also sometimes known as rippa or ripper cutters.

Roughing end mills, also known as hog mills, are used to quickly remove large amounts of material during heavier operations. A typical end mill may be referred to as an “upcut spiral” by the cnc router world. These types of milling cutters have the cutting teeth on both sides.

Slab mills are made from high speed steel.

0 komentar:

Posting Komentar