The wings of flared walls should be located with respect to the direction of the Tie bolt holes are provided for the installation of tie bolts between the flared end section and the adjacent pipe.

Ample right of way or easement is available.

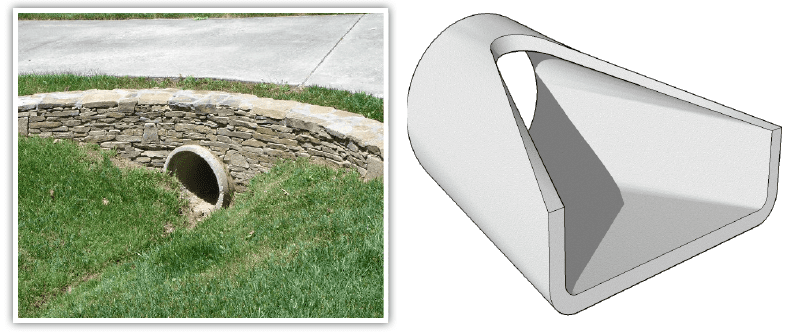

Flared end section vs headwall. Culvert flared end sections have many advantages. • existing groundline profile (shown as dashed line) and finished grade (shown as solid line). Flared end sections provide a less expensive option in areas of lower visibility.

Headwalls, wingwalls, drainage inlets, flared end sections, inlet and outlet structures, shown and labeled. End section conformed to fill slope: Pipe coupling and joint details;

Properly constructed headwalls and endwalls improve pipe efficiency while reducing erosion around pipe installations. Calculations shall be submitted with plan review. They are used to keep the earth away from pipe openings and provide support for bridges and roadways.

Projecting form fill (no headwall) 0.9: Flared end section (fes) headwall concept. Flared end headwalls are a type of retaining wall, commonly found near waterways.

Higher than the top of the drain pipe outlet section: Cost less than other types of concrete headwalls. Use additional longitudinal bars if spacing exceeds 30 inches on larger end sections.

The concrete flared end sections are. A conduit that is declared to be a culvert link may have a headwall node at either end. Headwalls (left image above) can be used as a retaining measure while adding visual interest in areas of high visibility.

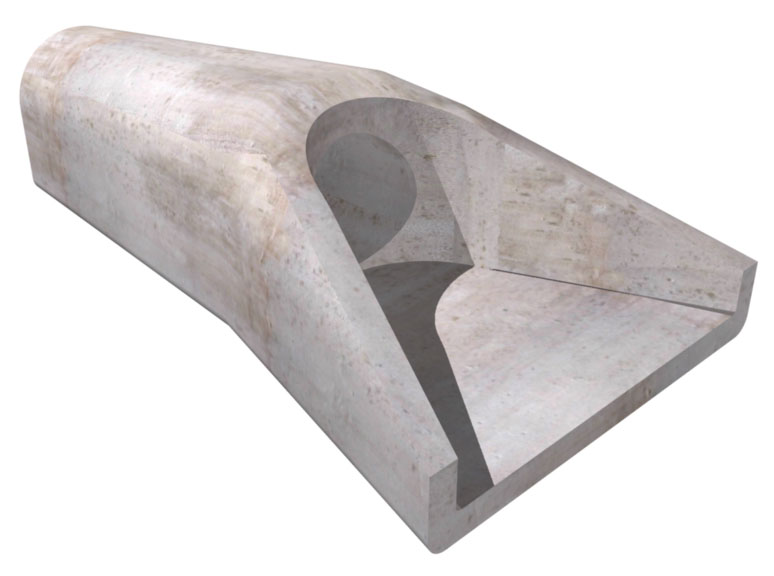

Metal and plastic flared end sections: Approach velocities are between six (6) and ten (10) feet per second. End sections are manufactured in accordance with applicable portions of astm specification c506.click here for information on trash guards.

Only a conduit link can be used to model a culvert. Perimeter of fabric nonwoven geotextile fabric centered provide a double layer of 12 x 12 geotextile fabric. Corrugated metal pipe or pipe arch :

Location manholes or structures shall be installed at each deflection of line or grade. Reduce erosion at ends of culvert. Precast concrete flared end headwalls offer convenience, time.

36 key rcp standard indices. Headwall or headwall with square edge wingwalls: Riprap or geotextile, for outlet protection materials

=user name plot scale = =. Flared end sections fit to either cmp or concrete are also considered straight inlets. Approach velocities are low (below six (6) feet per second).

Higher than the top of the drain pipe island over inlet height: The user may model projected or mitered end treatments on a culvert link with a connection to a cross section or outfall node. Soffit soffit refers to the inside top of the culvert.

• all flow line elevations. Block of aggregate shall be ca11 coarse aggregate placed over drain 12 x 12 x 6 block of ca5, ca7, or. Lets you define the slope correction factor to be used in inlet control calculations.

Flared end section (fes) headwall concept. If the conduit is a culvert, define the nomograph form to use in culvert calculations. Keep the culvert opening free from grass and weeds.

Increase stability with greater bearing area. Beveled edges, 33.7 or 45 degree bevels: Mitered (beveled to conform to fill slope) 0.7:

Under inlet control, standard flared end sections perform much better than mitered pipes, slightly better than headwalls with sharp inlet edges, and slightly worse than headwalls with grooved or rounded inlet edges. For single, twin, or triplebarrels; End section conforming to fill slope:

Coarse aggregate • section 902: Identify location of items by plus station and station offset distance. The sloping wing walls coincide with the embankment slope.

Safety and longitudinal bars are not required on 30 inches and. Completely wrapped in nonwoven opening. Flared, improved, or tapered inlets indicate a special entrance condition which decreases the amount of energy needed to pass the flow through the inlet and thus increases the capacity of culverts at the inlet.

Headwalls and endwalls support the road and protect the ends of the pipe. Standard flared end section for metal pipe culverts, or geotextile, for inlet protection diversion dike height: A longitudinal bar is required for cross drainage end sections when the span is greater than 30 inches.

The end of culverts can be treated with a variety of options depending on the situation.

0 komentar:

Posting Komentar