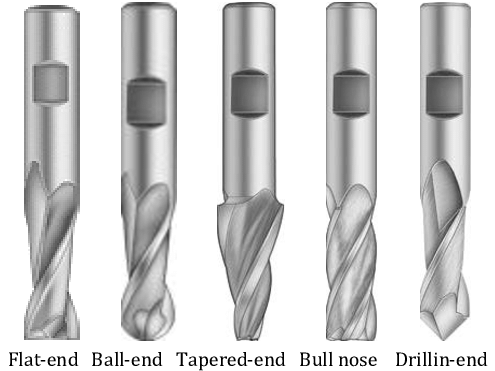

In the past, before the days of cnc machining centers, the tapered end mill was responsible for adding draft to molding surfaces and relieving fitted blocks. Those designed to cut axially are known as end mills.

With added strength and reduced deflection, the benefits of a tapered end mill can be significant, and extend to a much broader range of industries and applications beyond just mold tool and die.

Tapered end mills are used for. Conical cutting tools manufactures a wide range of standard, specialty, performance and custom end mills for customers all across the metalworking industry. Different sizes for your needs. Flat, corner radius, and ball end, 2 flutes, 3 flutes, 4 flutes, and 6 flutes taper mill.

Tapered end mills are center cutting, 3 flute high speed steel tools designed for side milling, contouring and machining angled slots. Taper mills or conical mills produce grooves, holes, or milled sides with a sloped angle. It is distinguished from the drill bit in its application, geometry, and manufacture.

Visit the website to find a variety of high quality taper end mills being offered for sale. Using tapered end mills on globalspec. If… a tapered end mill is.250 diameter at the tip (small end diameter) and expands to a.375 shank diameter then… calculate the speeds and feed just like you would for a.250 diameter end mill why?

Not all mills can cut axially; They are used specifically for designed parts that require an angled side wall. Can also be used for automobile curved surfaces.

While a drill bit can only cut in the axial direction, most milling bits can cut in the radial direction. They could be used in the tailstock of a lathe to bore holes. Each end mill has flutes on its cutting head that carry chips away from the workpiece to prevent damage to the end mill or workpiece.

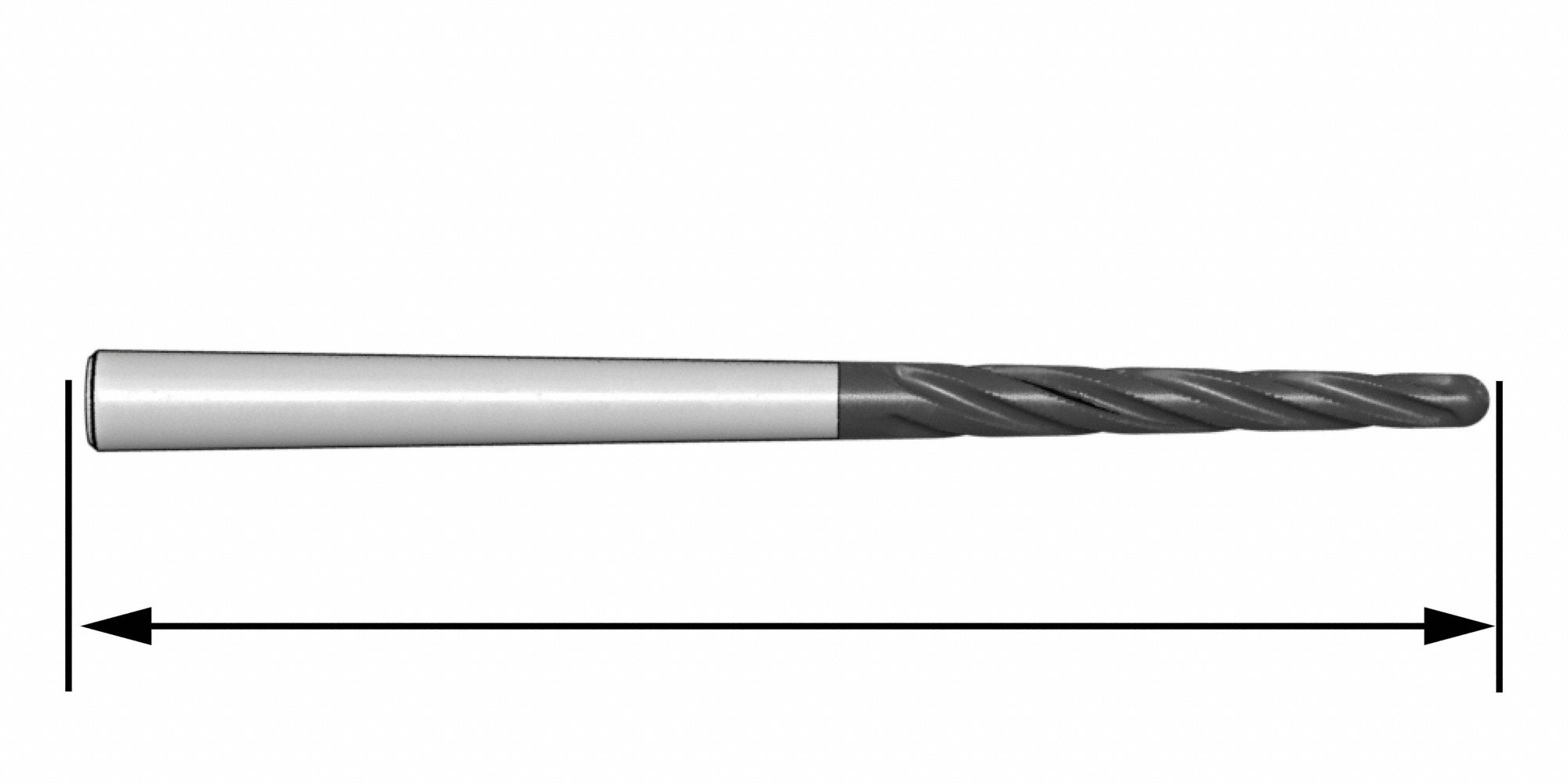

Ideal for use in die cast dies & molds. By the way, i do have a bunch of tapered end mills, bought when the local ge die shop auctioned off. The long length design of this tapered, ball profile miniature end mill optimizes it for accurate deep cavity machining.

They are used for making dies with specific draft angles on the walls. Betalent taper end mills have different end and flutes for different machining situations: Available tialn coating withstands high heat, allows.

Even a slight taper offers an increase in tool performance over the same tool with a straight neck. Also known as taper degree end mills, they're often used to machine angled slots in dies and molds. An end mill is a type of milling cutter, a cutting tool used in industrial milling applications.

Originally an end mill was used to remove material using only the cutting flutes on the side of its diameter. Learn more about chapter 6: 5/10/20/30/40/50/60 degree tapered end mill.

In cnc machining, taper end mills are used in many industries for a large number of applications, such as walls with draft or clearance angle, tool and die work, mold work, even for reaming holes to make them conical. They are three flute, square end, with a 30° helix. Tapered ball nosed end mills.

I tried to use one for reaming a tapered hole once and it made a mess, leaving chatter marks in the hole. So this would involve approaching the workpiece from the side, moving in the x and y axes only to remove material with the side edge of the tool. All are center cutting, allowing plunge cuts into a surface.

They were used in horizontal milling machines , and vertical mills too. The #2 morse taper has been around for a long time. Taper end mill 2 flutes.

Solid carbide tungsten steel 2 flutes tapered ball nosed end mills, coated, radius 0.25 to 2.0mm, cutting diameter 0.5mm to 4.0mm, cnc end milling cutter and woodworking router bit, used for engraving and carving machining, profile machining. A small diameter taper end mill that standardizes maximum taper angles up to 15 degrees. · the corner radius design from the edge to the periphery ensures less cutting resistance, and the variable pitch design minimizes chattering and vibration.

Solid carbide taper end mills by ab tools, inc. All of my tapered end mills are marked with the side angle in degrees. Because the tip is the weakest, most fragile portion of the tapered end mill.

Proudly made in the usa by ab tools, inc. Ideal for machining high hardness materials. Solid carbide models are 100% precision ground and inspected to insure complete uniformity and reliability required in the precision mold industry.

Most mold core and cavity finish work is either done in the sinker edm, wire edm or high speed milling machine. How to calculate tapered end mill speeds and feeds: I suppose if you had the material and the need, you could fabricate a cylindrical adapter, and hold the adapter in a collet,

0 komentar:

Posting Komentar