The wall leg of the kickout should be applied over the housewrap cut a 2 ft square piece of housewrap and tuck one edge into the horizontal cut (the same one the first piece of housewrap was slipped into) and up under the housewrap on the wall by at least 5 in. The flashing can be soldered step flashing or a prefabricated piece of its own.

View our wide range of flashing materials available to order online including barge cappings, apron flashings,.

End wall flashing roof. Step by step endwall flashing installation instructions on a metal roof. These products are made up of strong metals and produce a long lasting life. Tape over the cut in the.

Designed to flash the roof to the wall of attached greenhouses. Our items are attainable at best industry rates. Such a system usually consists of copper counterflashing and base flashing in conjunction with roof composition flashing or coping.

Roof flashing is a thin material, usually galvanized steel, that professional roofers use to direct water away from critical areas of the roof, wherever the roof plane meets a vertical surface like a wall or a dormer. To emphasize the importance of proper roof and deck flashing, and to provide typical and enhanced flashing techniques for coastal homes. Also find here related product comparison |.

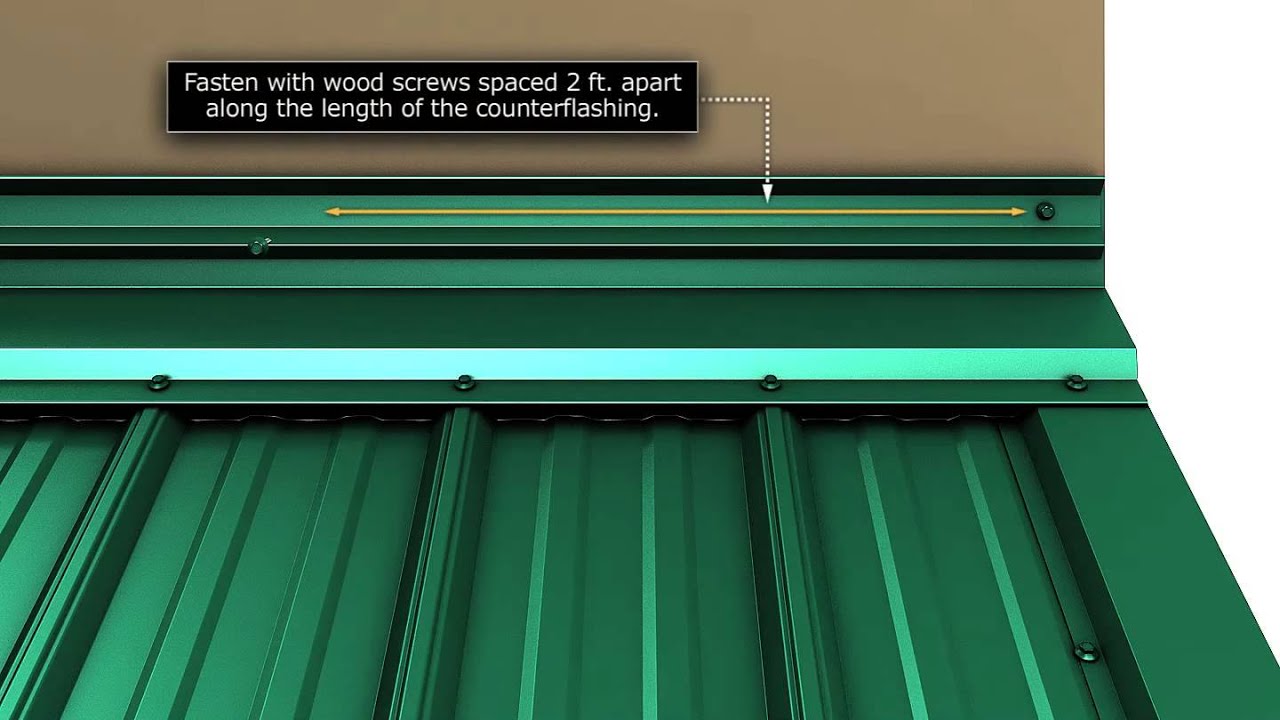

The counterflashing diverts water to the base flashing, which, in turn, diverts it to the composition flashing. Install metal roof endwall trim at the sidewall. Stramit® roof and wall flashing is generally manufactured from g300 steel with protective coatings of zincalume ®, galvanised or colorbond ®.

This kind of flashing is used to direct water away from the wall and down into the gutter. A flashing refers to pieces of colorbond®, zincalume® or copper installed to prevent the passage of water into a structure from a joint or as part of a weather resistant barrier system. Drip edge metal, valley flashing, dormer, chimney, and kickout flashing are types of roof flashing that shed water away from the connections between roofs, walls, chimneys, and other building assemblies

Flashing is installed to surround roof. Its purpose is to direct the water away from the edge of the roof, which will otherwise stream down and damage the side of the wall, and into the gutter. Now install the kickout flashing and step flashings up the roof as needed.

Then take the flashing off and fold it down where you marked it. There are also a few different roofing materials that you need to be aware of. Copper flashing is used wherever a wall intersects a roof.

Is not as common to see, but it is located at the edge of a roof section that ends at a wall. Other materials, such as colorbond ® ultra, colorbond ® stainless, uncoated stainless, copper and aluminium are also available. Roofing contractors generally need something to bridge the gap where the step flashing comes to an end and where the gutter begins.

3.12 flashing large roof penetrations 17 3.13 flashing small roof penetrations 19 3.14 expansion 20 3.15 standard roof flashings 21 3.16 non standard roof flashings, cappings 24 3.17 box gutters 25 3.18 barge gutters and capping 26 4.0 typical. Install emseal closure 3 inches back from metal roofing.make sure to screw through the flashing metal roof sheet wall cladding base flashing 2” overhang side elevation without overhang on eaves. Make sure to specify your roof’s slope!

Colours stramit® roof and wall flashing is available in a We are providing our patrons superior grade roof end wall flashing, which are highly appreciated by our customers. Leave approximately one inch past the edge of the gable trim on both ends of the flashing.

Using a pencil or a sharpie, mark where the flashing and gable meet.

0 komentar:

Posting Komentar