Horizontal and vertical end suction pumps. A range of versatile, energy efficient bearing frame pumps, suitable for horizontal or vertical mounting and incorporating the hidrostal screw centrifugal impeller.

It is generally used for pumping oil wells and viscous liquids applications.

End suction pump meaning. It takes some amount of fluid from one end, that is the suction side and positively displaced in the discharge side. Savvy and dependable, they are appropriate for a scope of pumping applications. Impeller of single suction pump has only one water inflow end, while double suction pump has two ends;

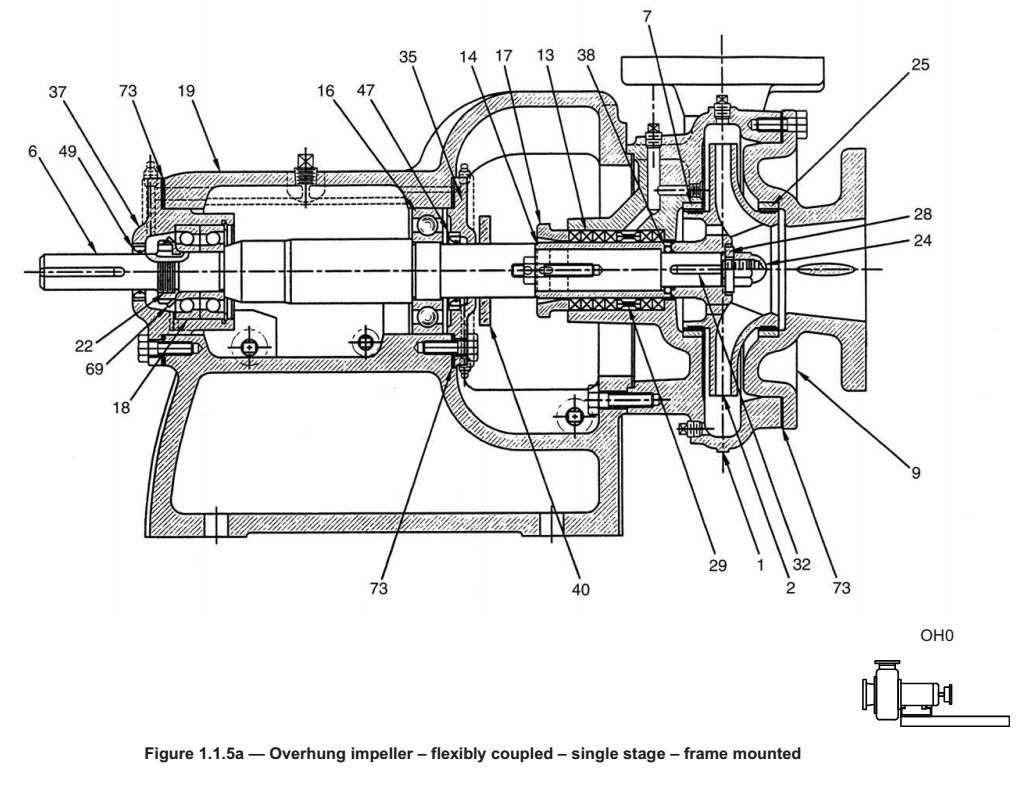

An end suction pump is a type of centrifugal pump where the suction is axial and the discharge is at 90 degrees to the suction. They are almost always single stage pumps, that is, they have only one impeller. Examples include, but are not limited to, pumps complying with ansi/hi nomenclature oh0 and oh1,

They function as a check valve, but they also have a strainer affixed to their open end. Also known as volute pump, standard pump, horizontal suction pump. A type of centrifugal pump that has a casing with the suction coming in one end and the discharge coming out the top.

The suction pipe means the pipe at the suction side. A typical centrifugal pump, the workhorse of industry. 3 the act or process of producing such a force or condition.

The direct flange mounted motor is spigoted onto the bearing frame and eliminates the possibility of. One end of this pipe is connected to the center of the impeller or the inlet of the pump which is known as the eye and another end dips into the water which is to be lifted. End suction pumps are one of the most common types of centrifugal pumps.

2 the force or condition produced by a pressure difference, as the force holding a suction cap onto a surface. End suction pumps are one of the most widely recognized kinds of diffusive pumps. Direct / close coupled end suction pump.

A pipe whose one end is connected to the outlet of the pump and other ends delivers the water at a required height is known as a delivery pipe. It connects between the pump enclosed area and the water sump. The mechanical end includes those parts that support the impeller within the casing.

It connects between the pump enclosed area and the water sump. This pump meets the requirements of en 733 (din 24255). Impeller is a rotor used to increase the kinetic energy of the flow.

The aquavane ksb pump is a centrifugal pump that has a horizontal pump specification, sigle stage, suction centrifugal pump at the end. There are two main types of end suction pumps commonly found on the market today. This is the simplest and most common type of centrifugal pumping unit.

In this type of pumping unit the impeller actually mounts on the end of the motor shaft and the pump casing mounts right onto the face of the motor. This lining is designed to wear out and be replaced over time. The mechanical end of the pump includes the pump shaft, sealing, bearings and shaft sleeve.

In this pump, volume at each cycle of operation is constant. Fluid flows into the single suction pump in only one end, but flows into the double suction pump i. A single suction pump having its suction nozzle on the opposite side of the casing from the stuffing box and having the face of the suction nozzle perpendicular to the longitudinal axis of the shaft.

The back pull out design is a standard feature and allows easy removal of the impeller and shaft with the complete drive and bearing assembly while keeping the piping and motor in place. From late latin suctio a sucking, from. There are often multiple pump types that can be selected for the same water application, with each pump type having its own.

Usually of overhung hung impeller type in which the impeller is mounted on the end of a shaft which is. These components are designed to perform specific tasks: They are almost always single stage pumps, and one of the most cost effective types of centrifugal pumps.

The primary difference between single suction pump and double suction pump is: A foot valve is found at the end of a pipeline in a suction lift application. 1 the act or process of sucking.

Many designs have a centre line discharge to comply with worldwide or regional standards. Manufacturers provide a range of materials of construction, sizes, and designs for applications involving water at ambient temperature, abrasive slurries, high pressure. What is an end suction pump?

This pump is widely used in the palm oil industry.

0 komentar:

Posting Komentar